CLICK HERE to learn more about pickup recharing with rare earth magnets. |

My my my what stories guitars often tell. This Steel was made in very late 1947 or early 1948, ...during the period that the USA was recovering from the Depression and WWII. American industry had still not recovered from a shortage of industrial materials although distribution of military-industrial surplus and the transition from war industry back to civilian industries was well under way. Many materials were still in short supply, with a lot of recycling still in process; But American civilian industries had learned to do well from 10 years of previous dire shortages. Many guitar manufacturers came up with creative ways to get around scarce materials and make do quite well, and even how to use what they learned in producing low priced products to sell to a public that too was recovering from dire econonomics during the previous 15 years; Enterprising upon making a number of versions of otherwise the same basic products; Increasing the price of basicly the same products by adding small amenities to the basic product. In the example of this steel guitar, it's fretboard was silk-sreened on while a bit more expensive models of the same guitar sported plastic fretboards. This Steel also used surplus round magnets that had 2 opposite flat sides, and the donor magnet was broken into pieces by drilling a small hole and then striking a slightly larger nail or punch into the hole which would shatter the magnet into various size useable pieces. A larger piece was used on the small strings (less mass) end of the pickup blade while a smaller piece was used on the larger strings (more mass) end, having the effect of tilting the pickup for diffeent strings mass like we do today. The magnets were simply sandwiched between two parallel vertical plates, while one of those plates extended up into the pickup coil to become a bar pole piece for the pickup. If interested, see the pickup parts on the electronics page. Shown below are the pickups magnets sitting atop a VERY strong 2"x1/2"x1/2" N42 grade rare earth magnet that I will use in a vice jig to refresh the magnetism of the pickup magnets; Just getting them "warmed up" here. Notice that there is a cardboard shim between the pickup magnets and rare earth magnet; Were it not there the magnets would be VERY difficult to pull apart. |

See Next Page; Epoxying the Joints Continued. >>> |

Regal Lap Steel Flamed Maple Veneer Deco Great Depression - WWII era Page 5; Repairing The Electronics Housing. |

See Next Page; Epoxying the Joints Continued. >>> |

< |

< |

< |

< |

< |

> |

> |

V |

V |

< |

< |

< |

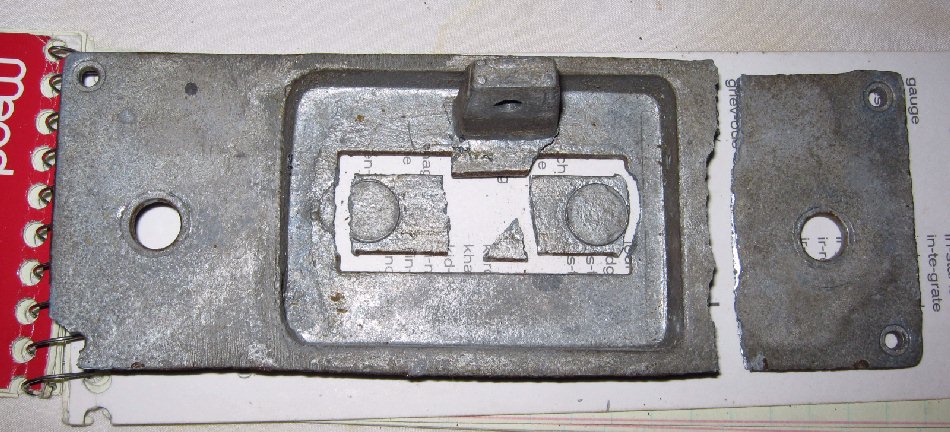

In this rear view we see that the electronics housing is broken in several places. It is cast / molded pot metal. Pot metal is soft compared to other stronger metals, and it breaks in jagged crystaline lines of stress. |

Because of it's softer nature, when pot metal breaks it stretches along the breaks. This makes the separate pieces slightly larger than they were originally. Although the jagged breaks fit back together quite well and tightly, some of the extra breaking length must be ground off somewhere so that the slightly longer pieces will fit back together. I ground the end of the piece with the round casting shown below, which provided room for the pieces to fit back together very well; Simply placed back together as shown below. Pot metal is made from various metal recipes and unless a person is a metalurgist or-such, then it is difficult to determine what metals are in the pot metal, which often contained a generous content of lead which has a low melting point. Pot metal is often very difficult to weld, braze or solder ....and a pot metal part can be ruined by getting it hot enough to solder while that heat is soaked up by the surrounding metal, requiring a lot of heat on the area to be soldered. So I made the decision to repair this electronics housing with epoxy which is a chore in itself to do right and work well. |

V |

Now we encounter another challenge. The tight fit of the crystaline pieces edges will not leave enough room for enough epoxy to hold it glued back together. Each joint edge could be ground to a "V" and the metal brazed or soldered, ...but that would require more work than it would be worth compared to epoxy for which both methods would need artistic dressing to hide the repair. See the solution further below. |

To solve the tight fit / epoxy challenge, I cut a channel along the edge of the breaks so that the epoxy will have room to establish a strong bond. The epoxy will squeeze out into the cracks when each piece is compressed together while laid on a sheet of safety glass which will bond the pieces fit perfectly flat. The edge previously shown has still not been channeled in the picture below, ...so you can see the difference between channeled edges and that edge not yet channeled. |

< |

And here is the same piece channeled, along with other channeled pieces stacked together here. Notice that all of the channeling is done in an irregular rather than smoothe manner; Irregularity gives "teeth" for the epoxy bond to grip onto. All pieces are ready to be epoxied. A ground jumper wire will be installed between the pots mounts since the electronics housing's ground won't carry through the epoxied joint. |

My my my what stories guitars often tell. This Steel was made in very late 1947 or early 1948, ...during the period that the USA was recovering from the Depression and WWII. American industry had still not recovered from a shortage of industrial materials although distribution of military-industrial surplus and the transition from war industry back to civilian industries was well under way. Many materials were still in short supply, with a lot of recycling still in process; But American civilian industries had learned to do well from 10 years of previous dire shortages. Many guitar manufacturers came up with creative ways to get around scarce materials and make do quite well, and even how to use what they learned in producing low priced products to sell to a public that too was recovering from dire econonomics during the previous 15 years; Enterprising upon making a number of versions of otherwise the same basic products; Increasing the price of basicly the same products by adding small amenities to the basic product. In the example of this steel guitar, it's fretboard was silk-sreened on while a bit more expensive models of the same guitar sported plastic fretboards. This Steel also used surplus round magnets that had 2 opposite flat sides, and the donor magnet was broken into pieces by drilling a small hole and then striking a slightly larger nail or punch into the hole which would shatter the magnet into various size useable pieces. A larger piece was used on the small strings (less mass) end of the pickup blade while a smaller piece was used on the larger strings (more mass) end, having the effect of tilting the pickup for diffeent strings mass like we do today. The magnets were simply sandwiched between two parallel vertical plates, while one of those plates extended up into the pickup coil to become a bar pole piece for the pickup. If interested, see the pickup parts on the electronics page. Shown below are the pickups magnets sitting atop a VERY strong 2"x1/2"x1/2" N42 grade rare earth magnet that I will use in a vice jig to refresh the magnetism of the pickup magnets; Just getting them "warmed up" here. Notice that there is a cardboard shim between the pickup magnets and rare earth magnet; Were it not there the magnets would be VERY difficult to pull apart. |

Here the pickup magnets (wrapped in masking tape to keep them stacked properly) and rare earth magnet are jigged in my carpenters vice that will pull them apart in a straight line once the charging is finished; Otherwise uneven movement of separating them would diminish some of the recharging. I tap the pickup magnets vice jaw several times with a tack hammer 3 or 4 times each of the 2 days I keep the magnets in the vice jig; Tapping the pickup magnets vice jaw injects shock into them which makes the magnetism domains to realign even better with the rare earch magnet's. |

Then the sun rises, the birds chirp and the roosters crow, and I can go to bed after a very long day ! |

The task; Repairing or replacing this pot metal electronics housing shattered into several pieces. Top view: |

CLICK HERE to learn more about pickup recharing with rare earth magnets. |